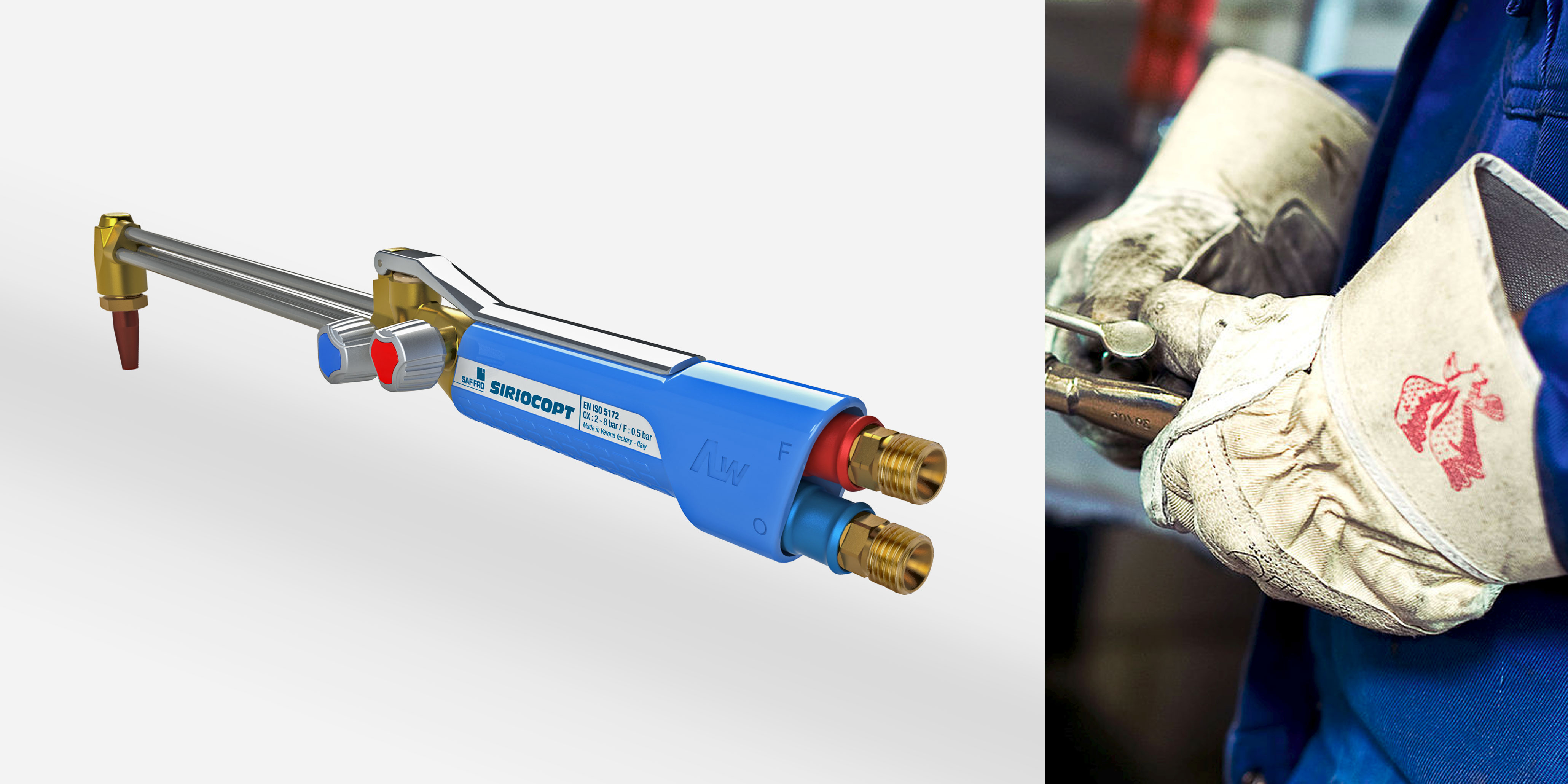

Integrated QUICKMATIC hose connectors – Convenience and safety on harsh work-sites

Oxygen cutting torches are heavy duty tools in use for decades without major evolution in their design. A careful analysis of exiting cutting torches in real environments clearly showed opportunities for improvement. The ability to separate the blowpipe from the gas supply pipes protects the tool during transport operations, prevents accidental damage and precludes any unauthorized use during nonworking time. The design-driven introduction of these feature considerably increases safety on work sites.

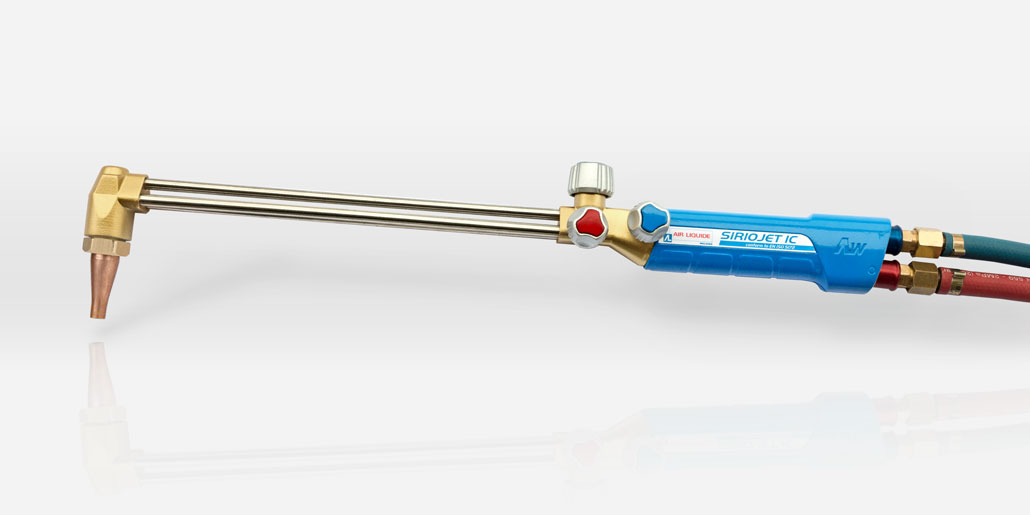

Ergonomic handle and oxygene lever – Fatigue-proof and precise cutting process

The Air Liquide cutting torches are distributed and used worldwide. The geometric design of the handle had to take into consideration international differences of anthropometric dimensions. Precise cutting operations must be supported as well as rough demolition activities. The lever assures fatigue-proof activation of the oxygen supply. In a 180 degree position it allows the blowpipe to be used like a standard welding torch. These ergonomic features represent unique selling points which help to strengthen the clients leading position in the market.

Universal product design allows cost-efficient derivation of two product lines

The geometric design was conceived in order to create two different product lines, one with cutting oxygen valve, the second with a cutting oxygen lever, with the same body molds and handle shells. Only the final tooling process differs between the two product-lines. Cost-efficiency by design.

- Client: Air Liquide

- Client website

- Siriocopt on Youtube

- Brochure Siriocopt (.pdf, 1,6MB)

- Other design projects for Air Liquide / SAF-FRO

Main challenges

- Precise translation of unique selling points in designlanguage

- Best ergonomic qualities in all real life use situations

- Body modeling for maximum material savings

Services provided

- Innovation impulses

- Product design

- 3D-surface and solid modeling

quickpartners.net

quickpartners.net